CASE STUDY

Rapid Prototyping

The Challenge

In this case study of rapid prototyping and 3D printing, a customer required a specific profile to fit a need to their portfolio did not meet. Additionally, the part had never been purchased or produced by the customer before. This presented a unique problem that for both Engineered Profiles and the customer to overcome.

The challenge was to design a part, prove it out, and develop a tool in time for the customer to take to market at an industry trade show. The only way to make this economically possible and meet the time constraints for all involved-was through rapid prototyping.

The Solution

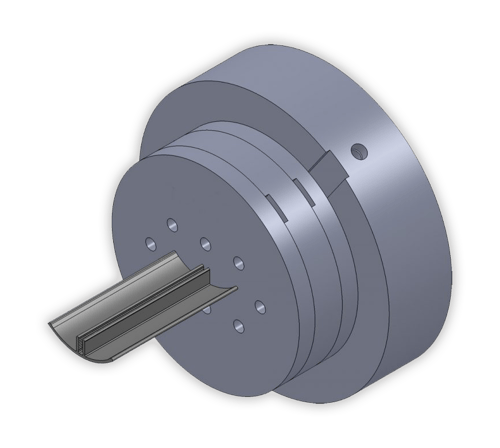

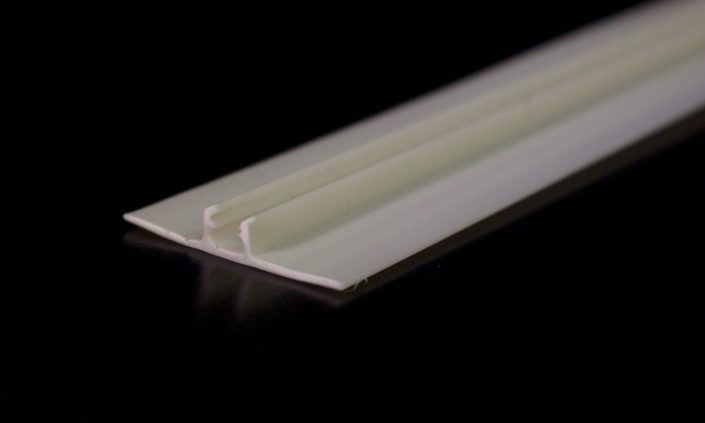

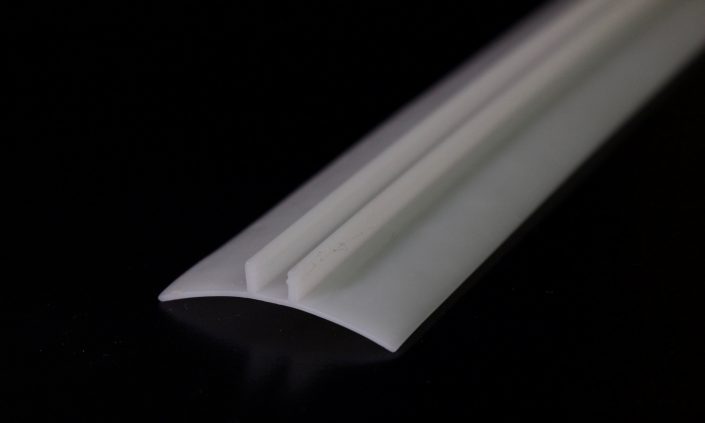

The conceptualization portion of the task was undertaken by the Engineered Profiles design team. This group routinely works with engineering teams from across a wide spectrum of customers to design new, custom profiles that accomplish specific tasks. Since the part in question needed to function with other existing profiles-while still being aesthetically pleasing to customers-a new rapid prototyping process was required. Once the overall concept of the part had been finalized in modeling software, the part was built with a 3D printer to confirm the final design elements performed as expected.

In the past, a project like this would have required Engineered Profiles in to build a tool in order to test an unproven part. This time around, Engineered Profiles was able to create a proof of concept overnight. This concept part was used by the customer to approve initial designs before tool building began. This approval process included checking the form and function of the rapid prototype part in real-world applications.

The Result

The method of engineering a part for a plastic extrusion, and then 3D printing a test piece, has rapidly increased the speed at which a new part can be developed. This new approach led to 90% of the design and approval process being handled before tool building commenced. Armed with this information, engineers were able to create finalized tooling package capable of producing a product identical to the 3D-printed part.